MOVILINK® DDI digital motor interface

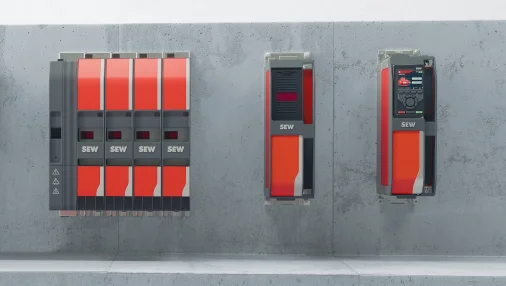

The MOVILINK® DDI digital motor interface transmits performance, brake and diagnostic data from the inverter to the motor. Start the data revolution in your application, too – whether it's a centralized or decentralized installation topology, a synchronous, asynchronous or linear motor. You never again have to wonder which encoder goes with which interface. It will always match!

MOVILINK® DDI lets data flow

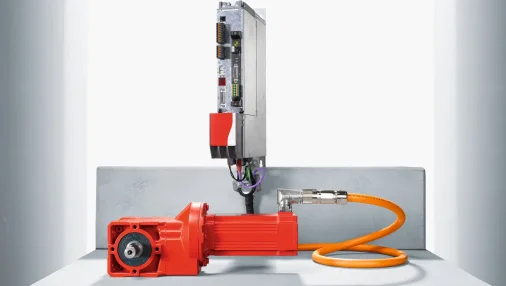

Single-cable technology forms the basis for the energy supply and seamless data exchange. In technological terms, this means you only need one hybrid cable to supply the motor with power and establish communication with the frequency inverter, no matter how extensive your system is. Movement is already underway – data is already flowing.

In practical terms, this also means you save time and money during installation, because the exceptionally robust and high-performance design of the cable with coaxial data line makes it possible to implement compact installations with ease.

The technology in detail

Commentary

What MOVILINK ® DDI can do and what it offers you

A quote from Steffen Quadt – Product Manager MOVILINK® DDI and Encoder Technology

Further information

Find out more

Data and documents

Operating instructions, catalogs, brochures and lots more! All technical data for MOVILINK® DDI!