Looking to completely do away with conventional charging contacts? Would you rather make the track freely traversable in the available space and transfer energy to a battery or storage capacitor at specific points? Then we have the solution for you – MOVITRANS® spot. You can use this innovative system to ensure perfect, contactless energy transfer.

Secure high ground clearance and increase performance and flexibility

Our MOVITRANS®technology works on the principle of inductive energy transfer. This is where energy is transferredwirelessly and without contact through an air gap. As a result, the electromagnetic coupling is completely wear-free, low-noise and low-maintenance.

Contactless energy transfer is particularly useful in production facilities where machines and systems are flexibly connected over lengthy distances. In the past, high-maintenance conveyor belts or vehicles requiring a human driver were used for this task. Nowadays, mobile transport systems are used to easily bridge such distances. Our MOVITRANS®is the perfect power supply system for this very scenario. This is especially true in dusty and dirty areas.

Thanks to MOVITRANS®spot, the vehicles are not dependent on fixed tracks or line cables and can move autonomously and freely around the available space. All it takes is a stationary hold point above a field charging plate to inductively charge their energy storage units. Space-saving, quick and efficient. Thanks to this wear-free, low-maintenance form of energy transfer, MOVITRANS® spot ensures aparticularly high ground clearance and flexibility, specially designed for mobile systems.

Ask us for advice

- Our experts are familiar with your industry and requirements

- Our global network ensures we are close at hand wherever and whenever you need us

- We have the expertise and tools to provide you with the best possible support and advice

Point-based, wear-free, low-maintenance and safe

Cut costs – for investments, startup and operation

In short, the MOVITRANS® spot contactless power supply system is the ideal choice if you are looking tokeep costs lowand boost productivity.

One key consideration is that our engineering software makes the startup and use of contactless MOVITRANS® technology extremely straightforward.

The benefits for you

-

Flexible usage

This is possible thanks to the innovative MOVITRANS® spot technology, which also allows for use in public spaces. -

Optimized performance

Systems can simply be charged when the load is transferred and, depending on the application, a variety of charging strategies and capacities are possible. -

High ground clearance

MOVITRANS® spot transfers energy through an air gap between the loading plate and the pick-up. -

Easy customization

MOVITRANS® spot can be easily adapted to suit changing system tasks and modifications thanks to its system modules. -

Lower operating costs and higher energy efficiency

MOVITRANS® spot is easy to use, sustainably minimizes maintenance costs and, thanks to its state-of-the-art component technologies, is highly efficient.

System features

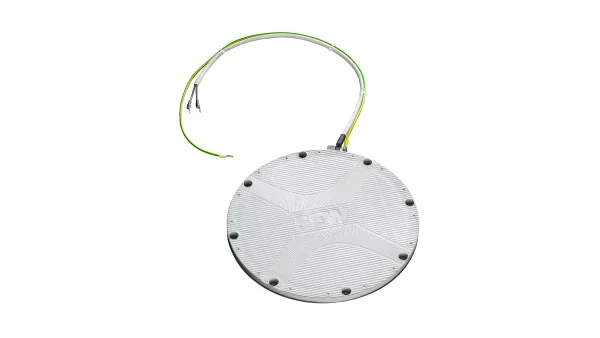

MOVITRANS®spot is made up of both stationary and mobile system components. They can be quickly and easily integrated into existing automation systems. The nominal air gap between the point-based charging plate and the pick-up is 20 mm. This makes it possible to achieve high transmission power even with a high ground clearance.

The technology at a glance:

- Compact, robust aluminum housing

- Can be installed directly on the travel section

- All connection cables pluggable

- Maximum efficiency even in the partial load range

- More electrical power per journey thanks to parallel operation

- Software support when starting up and operating the system

- Robust aluminum housing

- Direct installation near the TES supply unit

- Compensates the supply cable and field plate inductance

- Degree of protection: IP65

TFS10A and TFS50A field plates

- Inductive, point-based charging

- High charging capacity of up to 11 kW

- Suitable for use with forklifts

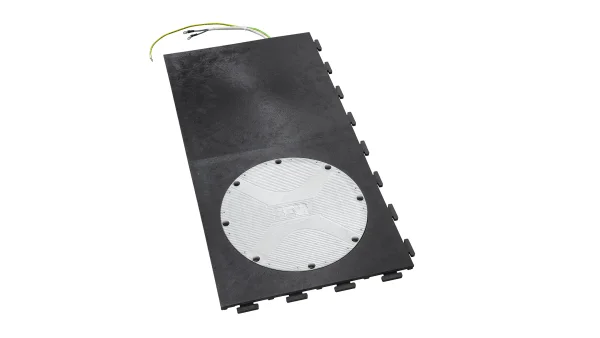

- Can be fitted in the floor (TFS10A) or with installation plates (TFS50A)

- MOVITRANS® spot with TFS50A can be installed without disrupting the floor.

- The surfaces can be quickly assembled and disassembled by connecting the installation plates with groove and tongue using a puzzle system. This increases the flexibility and adaptability of your factory.

Pick-up with TDM80E110-D06-B03-0 direct connection

- Nominal power: up to 11 kW for 4 minutes

- Different types for different output voltages

- Engineering via EtherCAT®/SBusplus

- Nominal voltage: up to DC 60 V

- Suitable for outdoor use from -10 °C to +40 °C

- Nominal voltage: up to DC 350 V

- Suitable for outdoor use from -25 °C to + 40 °C

MOVI‑DPS® (Drive Power Solution) EKV energy storage unit

- Storage unit can be configured to suit energy requirements

- Energy storage or peak load buffering through double-layer capacitors

- Fast and direct energy intake and energy release

- High number of charging cycles possible

- Storage modules with 100-F or 350-F cells can be connected.

- Additional signal cable can be connected to monitor storage voltage and temperature.

Key

-

1Stationary: TES30 decentralized supply unit

-

2Stationary: TCS50 compensation box

-

3Stationary: TFS10A and TFS50A field plates

-

4Stationary: TIS30A installation plates

-

5Mobile: TDM80E pick-up

-

6Mobile: EKV energy storage unit

Dr. Jochen Mahlein, head of the Charging Technology for Mobile Systems business area:

"The MOVITRANS®spot point-based energy transfer system represents the next stage in the systematic development of our long-standing and successful portfolio of contactless energy transfer products. It is ideal for those looking for a wear-free, position-tolerant charging solution for mobile applications/vehicles with energy storage units in process workflows. MOVITRANS®spot offers accessible, underfloor systems for new buildings and flexible floor-mounted installations that can be retrofitted at any time to help build the adaptable factory of the future."